Furnteck Engineers proud to manufacture high-quality melting and holding furnaces designed for energy efficiency and optimal performance. Our innovative furnaces are engineered to meet the demanding needs of various industries, ensuring reliability and superior results in metal processing.

Industries That Use It

Our furnaces are widely utilized in the aluminium foundry industry, particularly in applications such as alloy wheel casting. Other industries that benefit from our technology include automotive, aerospace, and manufacturing sectors where precise temperature control and efficient metal melting are essential.

How It Works?

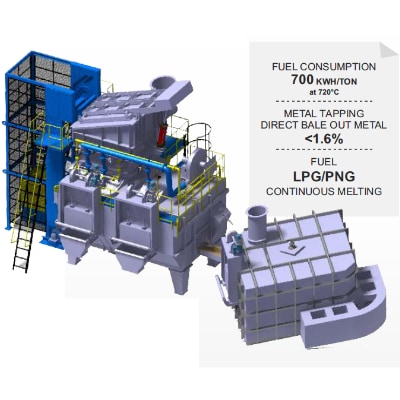

The furnaces designed by Furnteck utilize advanced technology to achieve high thermal efficiency while minimizing metal losses. The robust structure allows for easy cleaning and maintenance, ensuring consistent operation. The separate holding furnace is integrated with degassing machinery to remove impurities, which helps in producing high-quality metal. The furnaces maintain precise and uniform temperatures throughout the melting and holding process, providing optimal conditions for alloy production.

Specifications

- Fuel Consumption: 700 kW/Ton for melting at 720°C

- Metal Tapping Direct Baleout Metal: < 1.6%

- Fuel Options: LPG/PNG continuous melting