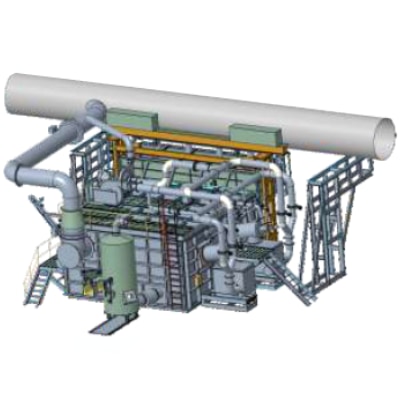

Furnteck Engineers proudly manufactures the Side Well Vortex Furnace, a cutting-edge solution designed for efficient aluminum recycling and melting. With a focus on energy efficiency and innovation, Furnteck delivers high-quality furnaces tailored to meet the diverse needs of the metal processing industry.

Industries That Use It

The Side Well Vortex Furnace is utilized in various industries, primarily in aluminum recycling and metal casting. Key sectors include:

- Aluminum Manufacturing: Used for melting scrap aluminum to produce new products.

- Metal Recycling: Essential in recycling facilities for transforming scrap metal into usable material.

- Foundries: Employed in foundries for casting aluminum components and products.

How It Works?

The Side Well Vortex Furnace operates by creating a vortex effect within the melting chamber, allowing for efficient heat transfer and uniform melting of aluminum scrap. The design promotes optimal fuel combustion and minimizes energy consumption, making it an environmentally friendly choice. The furnace is equipped with advanced technology that ensures consistent temperature control and effective degassing processes, resulting in high-quality melted aluminum.