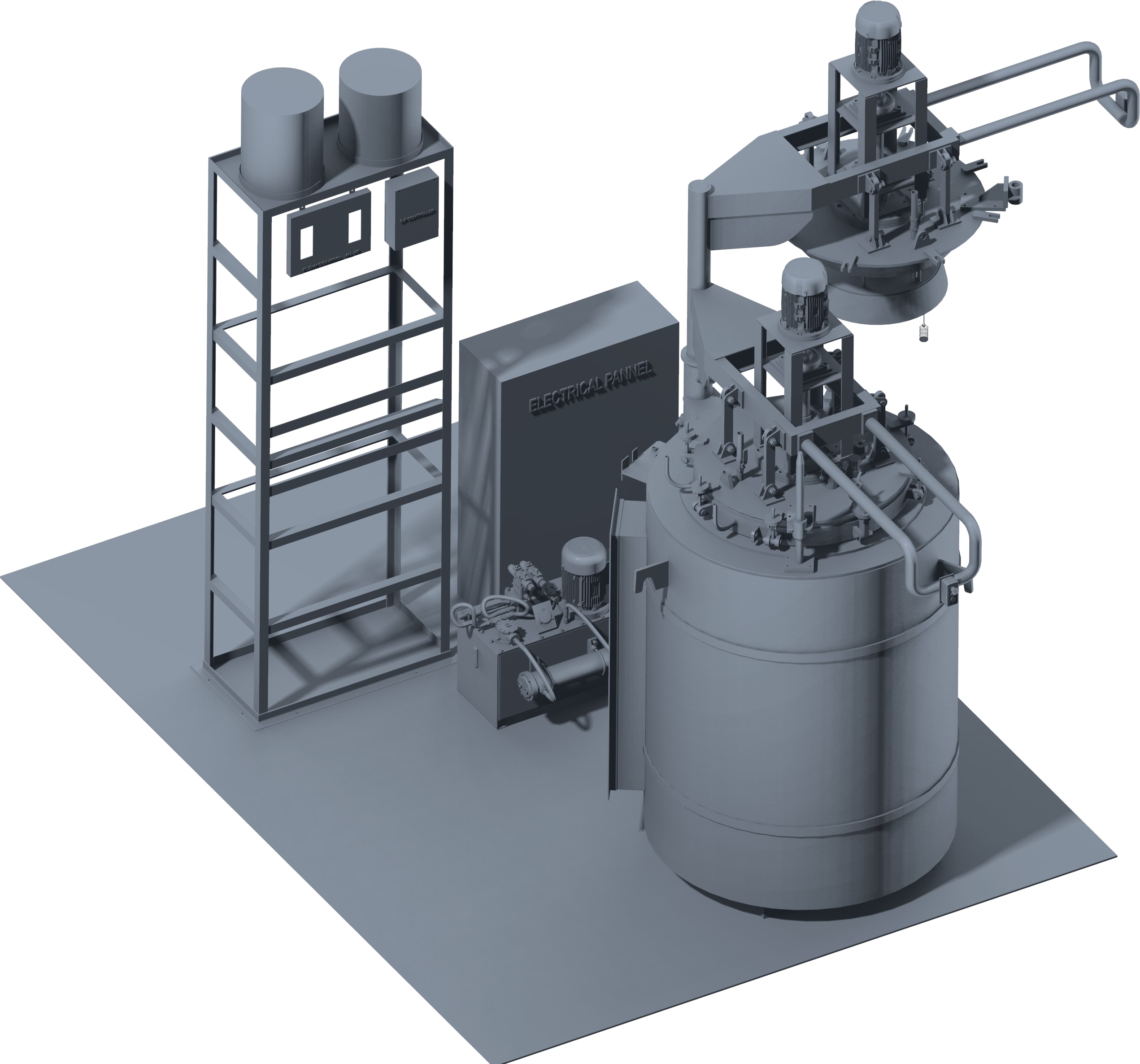

The Pit Type Carburising Furnace is a specialized heat treatment solution designed to enhance the surface hardness of components through the diffusion of carbon into the material. This furnace offers a controlled environment that ensures uniform carburization, making it ideal for treating large and complex parts. Its robust design allows for efficient processing, enabling manufacturers to achieve desired hardness levels while maintaining product integrity.

Industries That Use It

Various industries utilize the Pit Type Carburising Furnace, particularly those involved in manufacturing high-strength components such as automotive, aerospace, and machinery. Industries that produce gears, bearings, and other critical components rely on this technology to enhance the durability and wear resistance of their products, thereby extending their service life and improving performance under demanding conditions.

How It Works?

The Pit Type Carburising Furnace operates by creating a carbon-rich atmosphere within a sealed retort. During the carburizing process, the furnace heats the components to a specified temperature, typically between 850°C to 950°C, allowing carbon to diffuse into the surface of the steel parts. The atmosphere is carefully controlled to ensure consistent carbon content, which is essential for achieving the desired hardness levels.

Once the carburization cycle is complete, the components are rapidly quenched in oil or water to harden them further. This ensures that the carbon is locked into the surface, resulting in improved wear resistance and toughness. The process can be monitored and adjusted in real-time, providing flexibility and precision in heat treatment operations.

Key Features

- Robust Construction: Designed to withstand high temperatures and harsh operating conditions.

- Sealed Atmosphere: Maintains a controlled environment to prevent oxidation and ensure effective carburization.

- Energy Efficiency: Optimized for low energy consumption during operation.

- Customizable: Can be tailored to meet specific production requirements and accommodate various part sizes.

Specifications

- Temperature Range: 850°C to 950°C

- Furnace Type: Pit Type with sealed retort design

- Heating Method: Electric or gas-fired

- Capacity: Varies based on model (custom options available)

- Control System: Advanced programmable logic controller (PLC) for precise monitoring

- Quenching Medium: Oil or water

Benefits

- Enhanced Surface Hardness: Achieves superior surface properties for increased wear resistance.

- Cost-Effective Production: Reduces operational costs by minimizing energy use and enhancing throughput.

- Improved Product Quality: Ensures uniform carburization across all parts, leading to consistent performance.

- Sustainability: Offers environmentally friendly options with lower emissions compared to traditional methods.

Furnteck Engineers' Pit Type Carburising Furnace stands out as a reliable solution for manufacturers seeking to optimize their heat treatment processes while ensuring high-quality output.