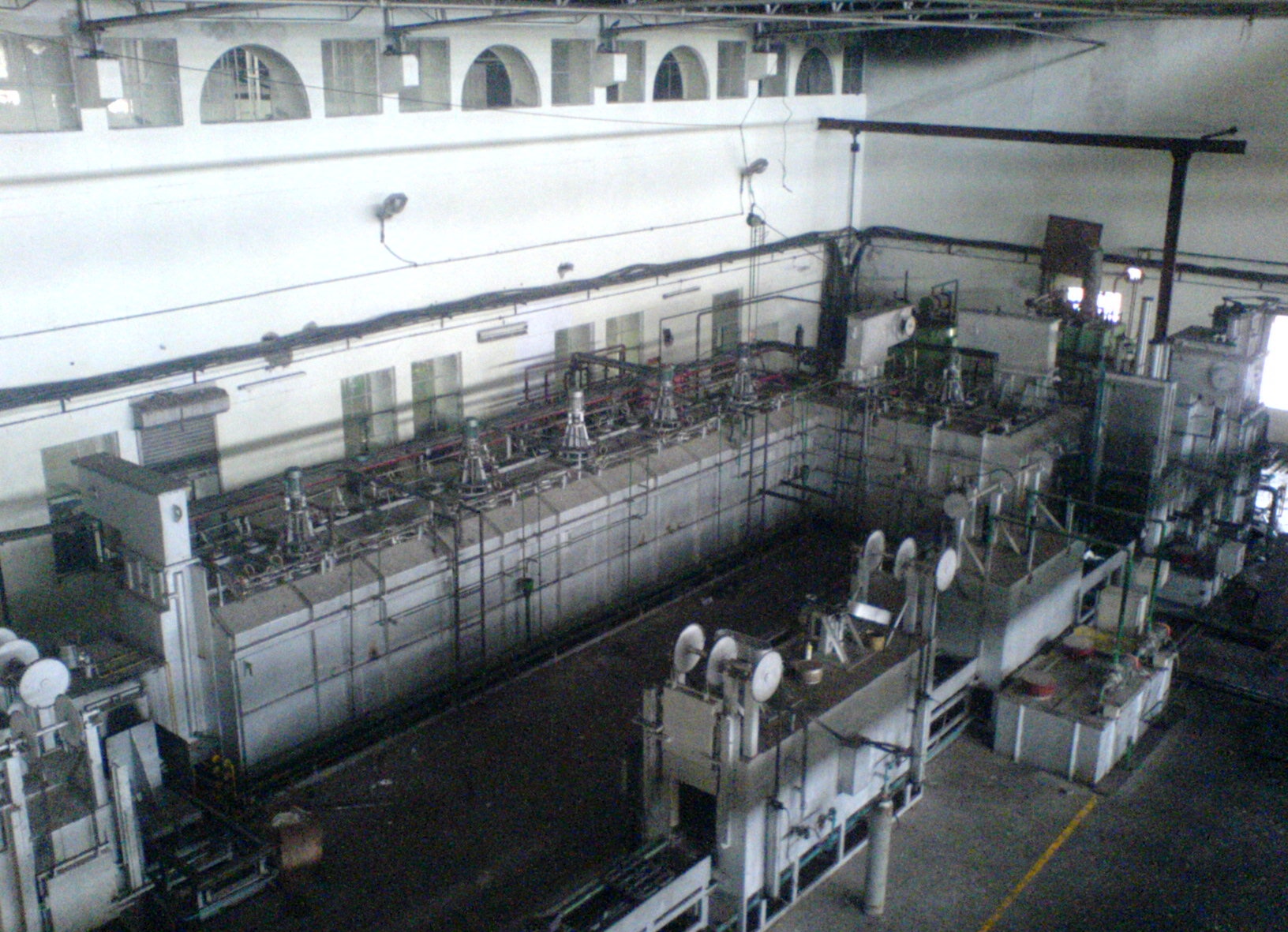

The Continuous Gas Carburising Furnace designed by Furnteck Engineers is an advanced heat treatment solution that provides efficient and consistent carburising processes for various components. Utilizing cutting-edge technology, this furnace operates continuously, ensuring high productivity while maintaining low operational costs. It is engineered to meet the increasing demands of modern manufacturing, offering reliability and precision in the carburising process.

Industries That Use It

Continuous Gas Carburising Furnaces are widely utilized across various industries, including automotive, aerospace, and heavy machinery. They are particularly essential in manufacturing components such as gears, axles, and engine parts that require enhanced hardness and wear resistance. The ability to produce high-quality treated parts consistently makes these furnaces invaluable in sectors where performance and durability are crucial.

How It Works?

The Continuous Gas Carburising Furnace operates by introducing a controlled atmosphere of carbon-rich gas into the furnace chamber. This process allows carbon atoms to diffuse into the surface of the steel components, increasing their hardness and strength. The furnace maintains a precise temperature of up to 950°C, which is essential for achieving optimal carbon diffusion rates.

The carburising cycle is meticulously controlled through sophisticated automation systems that monitor temperature, pressure, and gas composition. This ensures that the components receive a uniform treatment throughout the process. After carburising, components are rapidly quenched to lock in the desired properties, resulting in a hardened case with enhanced wear resistance.

Key Features

- Single track continuous gas carburising design for consistent production.

- Integration of advanced controls, including SCADA and data acquisition systems.

- Capability to operate with Endothermic gas or Nitrogen-Methanol atmospheres.

- Options for gas-fired or electric heating with radiant tubes.

- Fully automatic, PLC-controlled closed-loop system.

- Modular design for flexibility and ease of maintenance.

- Pneumatically operated door systems for positive sealing.

- Silicon carbide skid rails for smooth movement of charge.

Specifications

- Production Capacity: 150 kg/hr to 400 kg/hr

- Operating Temperature: Up to 950°C

- Control Systems: SCADA & Data Acquisition

- Heating Options: Gas-fired or Electric (Radiant tubes)

- Automation: Fully automatic PLC-controlled system

- Charge Handling: Robotic charge handling system available

- Skid Rails: Silicon carbide for durability

- Quenching Method: Guided quenching oil throughout the charge

Benefits

- Cost Efficiency: Reduces operational costs through continuous processing.

- High Quality: Ensures consistent product quality with advanced control systems.

- Flexibility: Capable of processing various component types and sizes.

- Reduced Downtime: Modular design facilitates easy maintenance and quick repairs.

- Enhanced Performance: Improves the hardness and wear resistance of components, leading to longer service life.

Furnteck Engineers' Continuous Gas Carburising Furnace stands out as a reliable solution for achieving superior heat treatment results, making it an ideal choice for industries that prioritize performance and efficiency.