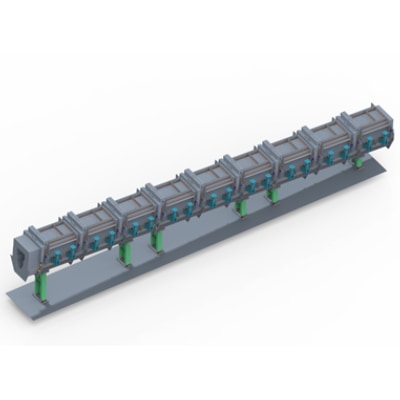

Furnteck Engineers proudly manufactures high-quality Electrically Heated Launders designed for the efficient transfer of molten metal in foundries. Our products are engineered with superior insulation and non-wetting refractory lining, ensuring minimal heat loss and optimal performance during metal transfer processes.

Industries That Use It

Electrically Heated Launders are utilized primarily in the metal casting and foundry industries. These industries require reliable solutions for the safe and efficient transfer of molten metals, including aluminum and other ferrous and non-ferrous materials. Foundries that specialize in aluminum casting, automotive components, and various manufacturing sectors benefit significantly from our advanced heating solutions.

How It Works?

Electrically Heated Launders function by using reliable heating elements that maintain the temperature of molten metal during transfer. The refractory lining prevents metal adhesion and ensures a continuous flow of molten metal. The design minimizes heat loss, allowing for efficient handling of materials while maintaining the integrity of the metal's properties.